Introduction: When Growth Outpaces Operations

Every organization reaches a point where its internal systems no longer match its ambition.

Processes that worked beautifully with 10 employees break with 50. Manual workflows that felt manageable at a smaller scale become operational bottlenecks at scale.

Teams begin firefighting. Leaders struggle for visibility. Quality becomes inconsistent. Small inefficiencies compound into serious cost, time, and customer impact.

This is the stage where most founders and CXOs realize:

"Our business has grown — but our processes have not."

In today's environment, speed, accuracy, and predictability are not operational choices — they are competitive advantages.

And yet, most companies continue to operate on outdated workflows, legacy habits, and manual interventions that slow down decision-making and limit scale.

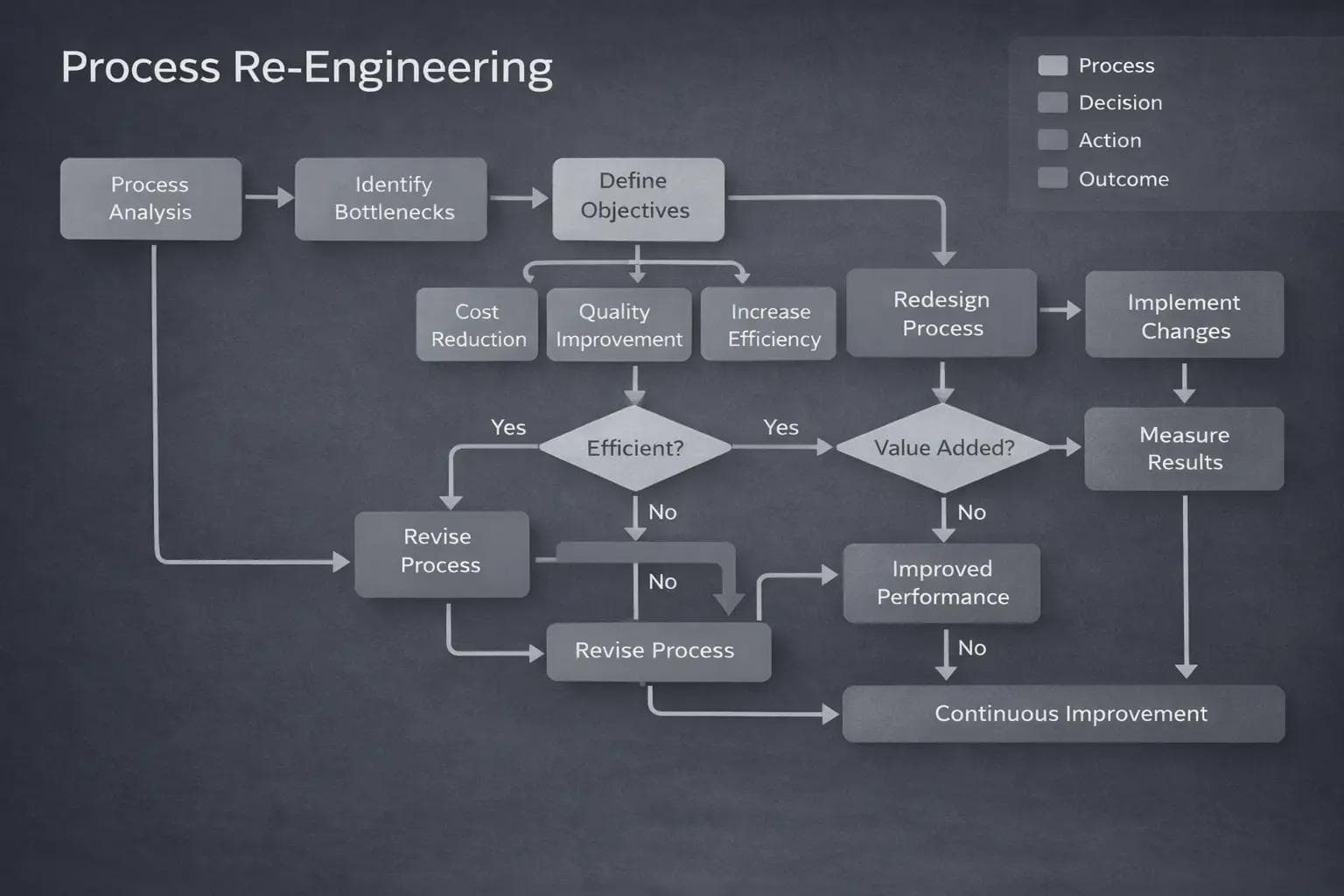

Process reengineering is not about "fixing inefficiencies."

It's about redesigning how work flows across the company so that growth becomes effortless instead of exhausting.

And when combined with thoughtful automation, it creates a system where execution becomes consistent, measurable, and scalable — independent of individual people.

This is exactly where Debox excels.

Why Most Processes Break (and Why Leaders Often Don't See It Coming)

Over the last decade, working with companies across India, the USA, and Dubai, we've observed that operational breakdowns follow a predictable pattern:

1. Processes Were Designed for an Earlier Stage of the Business

Most workflows were created when the company:

- had fewer people

- had fewer customers

- had fewer moving parts

- had fewer complexities

These legacy processes are never intentionally redesigned — they are simply stretched beyond their capacity.

The result? Workflow fatigue.

People work harder, not smarter. Systems strain. Errors rise. Lead times expand.

2. Every Team Builds "Its Own Way" of Working

Without standardized processes:

- Sales uses its own templates

- Operations uses its own formats

- Accounts uses their own review logic

- Customer service builds its own escalation flow

This creates fragmentation, confusion, and inconsistent outputs across the organization.

Consistency becomes impossible when every team defines its own definition of "how work is done."

3. Manual Work Dominates, Automation Is Fragmented

Most companies add tools without adding structure.

They implement:

- CRMs

- ERPs

- Spreadsheets

- Approval tools

- WhatsApp workflows

But without an integrated backbone, these tools become digital islands — disconnected, inconsistent, and dependent on human discipline.

Automation only works when the process underneath is clean.

4. Decisions Are Slowed by Missing Information

When information sits across:

- Excel

- Verbal updates

- Legacy software

leaders waste:

- time searching

- time verifying

- time escalating

- time following up

Decision-making becomes slow, reactive, and inconsistent.

5. High Dependency on Individual People

When organizations rely on "key people who know everything," the business becomes fragile.

If they are sick, resign, or overloaded — execution collapses.

Scalable businesses are process-reliant, not people-reliant.

The Debox Way: Reengineering Processes for the Next Stage of Growth

Unlike traditional consulting firms that deliver reports or theoretical frameworks, Debox brings a deeply practical approach based on:

- real-world observation

- on-ground interviews

- cross-functional mapping

- business logic automation experience

- change management

We don't just fix processes. We redesign execution.

Here's how we do it.

1. Process Immersion: Understanding How Work Actually Happens

We begin by studying the organization from the inside:

- shadowing teams

- observing workflows

- interviewing departments

- reviewing tools & templates

- understanding exceptions

- analyzing actual time spent

- mapping dependency chains

- studying communication gaps

This immersion gives us clarity into:

- What works

- What breaks

- What gets duplicated

- What creates delays

- What causes quality variance

- What leaders are unaware of

This enables us to design processes grounded in reality, not assumptions.

2. Redesigning Workflows with a "Zero-Based Mindset"

We rebuild processes using a zero-based approach:

- If we had to design this workflow today, how would it look?

- What is the fastest path from input → output?

- What steps add value and what steps add delay?

- What can be standardized?

- What can be parallelized?

- What decisions can be automated?

- What information is missing at each stage?

- How do we reduce human friction?

We then design:

- End-to-end SOPs

- Checklist-based flows

- Clear ownership rules

- Exception paths

- Approval logic

- Turnaround times (TATs)

Everything is designed for speed, clarity, and consistency.

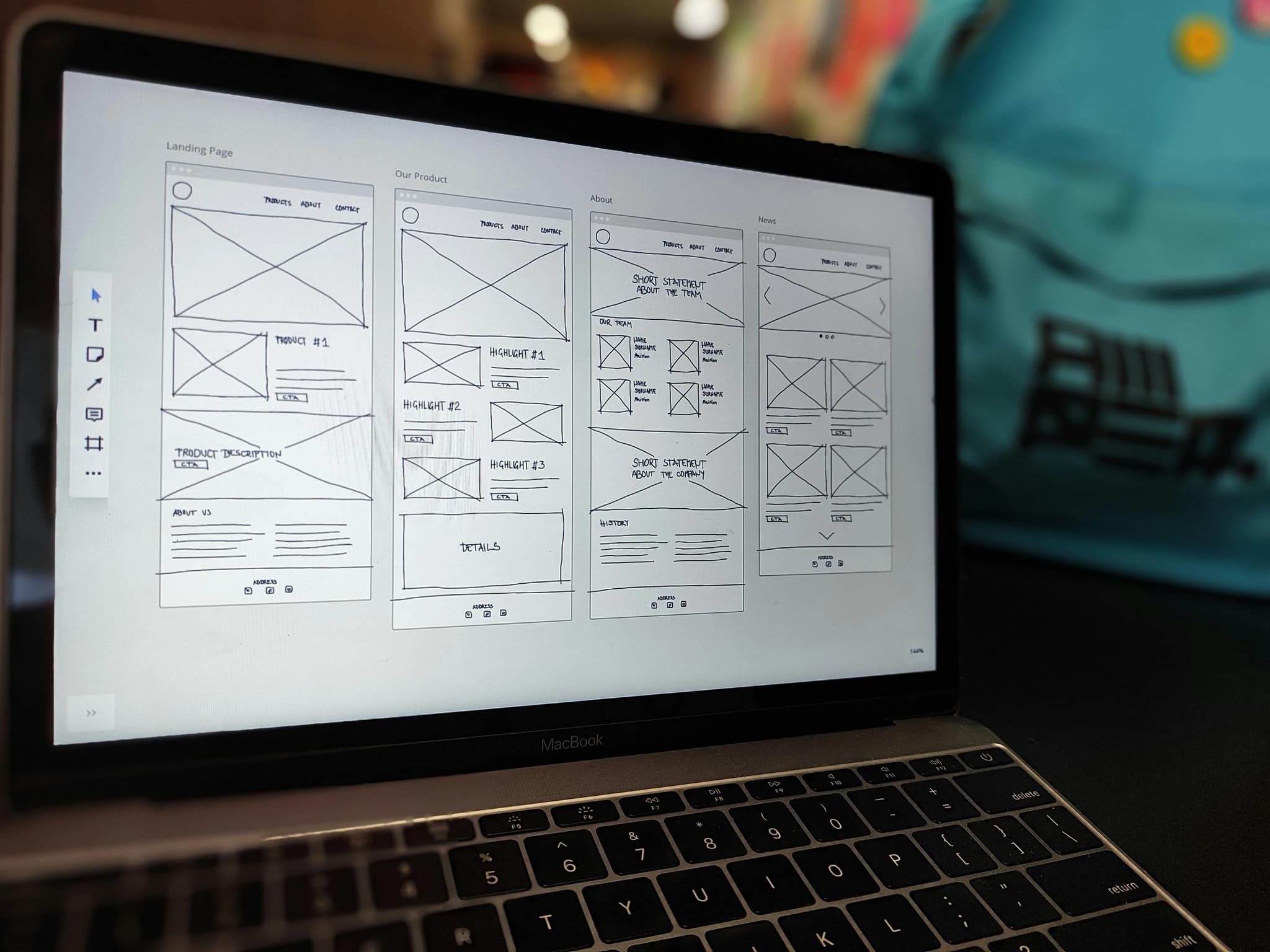

3. Designing the Automation Blueprint (Before Writing Any Code)

Most companies jump directly into automation tools.

Debox does the opposite.

We first create the automation logic, which includes:

- Input fields

- Auto-validations

- Trigger rules

- Auto-notifications

- Integration points

- Approval flows

- Data routing

- Reporting dashboards

This blueprint ensures automation is not "built around chaos" — it is built around clarity.

This is how we ensure automation actually reduces effort instead of adding complexity.

4. Building Custom Automation Through Zoho or Custom ERPs

Depending on the scale and requirements, we automate via:

- Zoho Creator

- Zoho Books / Inventory

- Zoho People

- Custom-built ERPs

- API-driven integrations

- Automated report engines

This includes features like:

- Digital forms

- Auto-generated PDFs

- Automated QC

- Maker-checker flows

- Real-time dashboards

- Escalation alerts

- Multi-level approvals

- Integration with accounting, CRM, POS

Our consulting background ensures: we automate what matters, not what is convenient.

5. Driving Adoption: Because Implementation Is Only Half the Job

A system is only as strong as its adoption.

Debox drives on-ground adoption through:

- User training

- Live testing

- Fixing edge cases

- Daily reviews

- Team coaching

- Behavior alignment

- Leadership updates

- On-ground troubleshooting

This is where most firms fail — but Debox excels because we work hand-in-hand with teams, not from the outside.

Business Impact: What Clients Actually Experience

Organizations that implement Debox's reengineering systems see tangible, measurable benefits:

✔ 25–45% Reduction in Turnaround Times

Because workflows become streamlined and unblocked.

✔ 30–70% Reduction in Manual Work

Because data, validation, and routing become automated.

✔ Higher Execution Accuracy

Because human dependency reduces, and QC is structured.

✔ Better Leadership Visibility

Real-time dashboards enable faster, smarter decisions.

✔ Lower Operational Cost

Fewer errors, fewer escalations, fewer delays.

✔ Teams Become More Confident & Productive

Process clarity eliminates confusion and reduces frustration.

Case Study: Legacy Manufacturing Firm (India + Middle East Markets)

A 50-year-old manufacturing company was struggling with:

- high manual reporting

- inconsistent production data

- unclear ownership

- repeated QC issues

- delayed approvals

- rising customer complaints

Debox undertook a 12-week transformation cycle.

Reengineering Achievements

- 18+ workflows mapped across Sales, Production, Stores, Dispatch, Accounts

- Clear, standardized SOPs

- Defined roles across 200+ employees

- Removed 120+ redundant steps

Automation Achievements

- Zoho Creator production module

- Automated QC & testing logs

- Real-time dispatch tracking

- Auto-generated invoices & challans

- Exception-based alerts

- Leadership dashboards with 62 KPIs

Outcome (90 Days)

- Production efficiency improved by 41%

- Error rates dropped by 67%

- Dispatch delays reduced by 54%

- Leadership visibility moved from weekly → real-time

- Customer satisfaction improved significantly

This was not a tech upgrade. It was an operational transformation.

Conclusion: Processes Don't Scale — Systems Do

Most leaders underestimate the hidden cost of inefficient processes: lost hours, repeated work, poor visibility, stressed teams, delayed decisions.

Process reengineering is not about fixing problems.

It is about rebuilding the operational backbone of the company for the next decade of growth.

When paired with intelligent automation, it creates a business that is:

- faster

- more accurate

- more predictable

- more scalable

- more mature

This is the transformation Debox brings — clarity, structure, automation, and real on-ground execution.